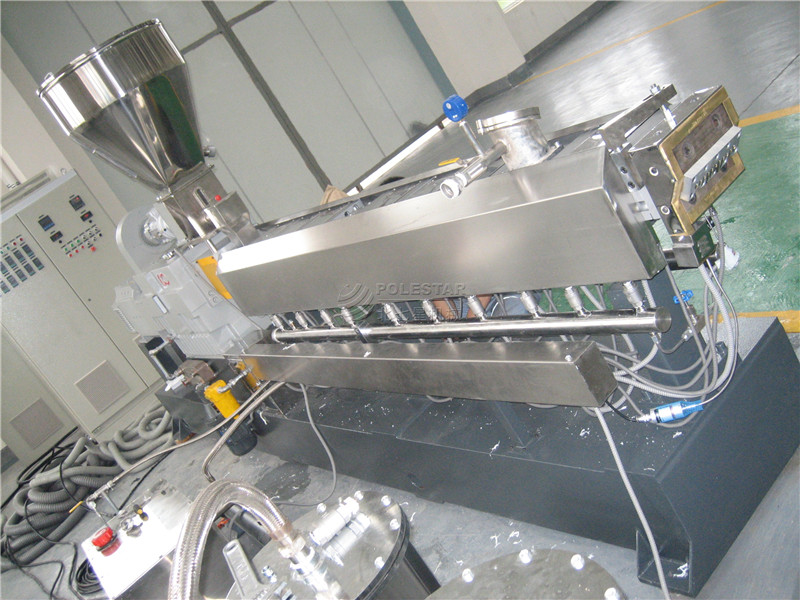

Yakakwira Inoshanda PET Granulating Machine

Hunhu

Iyo PET pelletizer inonyanya kuumbwa neinotevera midziyo: extruder, hydraulic screen changer, strand cutting mold, cooling conveyor, dryer, cutter, fan blowing system (feeding and drying system), etc. Shandisa parallel twin screw extruder kuti uve nekutonga kwakaringana tembiricha. , kubuda kwepamusoro nekushandiswa kwesimba kwakaderera.

Application

Iyo pet pelletizing muchina unoshandiswa kugadzira PET epurasitiki flakes kuita pellet kana granule.Twin screw extruder recycling & pelletizing system inoiswa kune tsvina zvinhu, izvo zvinoda yakakwira kugadzirisa kuita kwekunyunguduka, volatilization, kusefa nezvimwe.

Process Flow

Sikuru yekudyisa ( ZVINODA)→ Simba rekudyisa→ Parallel twin screw extruder → Hydraulic filter exchanger→ Musoro weMold → tank yekutonhodza mvura →Plastic standard cutter→ Yapedza kurongedza chigadzirwa.

Tsanangudzo Yakadzama Yechinhu Chimwe nechimwe

1. Screw Feeder: endesa zvimedu zvePurasitiki mumushini mukuru.

2. Kumanikidza feeder: feed material kune extruder neyakagadzirirwa kumhanya, kumhanya kunogona kugadziriswa.

3. Parallel twin screw extruder: plasticizing zvinhu uye kupera simba gasi.

4. High-speed Net exchangeing system uye Die-head: sefa zvinhu zvisina kuchena, kuita kuti kugadzirwa kugadzikane.

5. Tangi yemvura: kutonhora kwePET noodles.

6. Plastic standard cutter: cheka maPET noodles mumagranuel.

Competitive Advantage

1. Automatic PLC control

2. Nekutonga kwekushisa kwega

3. Kushanda kwakanaka & Kugadzikana kwekuita

4. Yakanyanya kushanda, kuchengetedza kwezvakatipoteredza uye kuchengetedza simba

Technical Data

| Extruder | TSK35 | TSK50 | TSK60 | TSK65 | TSK75 | TSK95 |

| L/D(mm) | 24-56 | 24-56 | 24-56 | 24-56 | 24-56 | 24-56 |

| Kumhanya kweMax (rpm) | 600 | 500 | 300-500 | 400-500 | 400-500 | 300-400 |

| Motokari Simba(kw) | 11-18.5 | 22-37 | 37-55 | 45-75 | 90-160 | 185-250 |

| Heater Power (kw) | 16 | 24 | 30 | 34 | 45 | 60 |

| Kubuda Kwakawanda(kg/h) | 20-80 | 50-200 | 80-300 | 100-350 | 200-500 | 700-1200 |

Zvigadzirwa zvikamu

Unoda Kuwedzera Denga kune Dhizaini Yako?

Bata nesu nhasi kuti uwane mazano ekugadzira.